Company profile

The company ART-tech, Slovakia s.r.o., was founded in 2007. The development of the company follows the production program of the trade, whose business in the field of metalworking began in 2006. Today it ensures the production of precise and high-quality components. We focus on custom, small and medium series production of parts intended for the engineering and other industries according to the supplied drawing documentation.

Extension of the new warehouse in 2023 – Bulk material warehouse with an area of 356 m2

Our company is trying to progress and help nature to heal, and that is why we installed a solar power plant with a capacity of 70 kW in 2023. It helps us cover 40% of our electricity consumption.

new 3 axis vertical machining center, vehicles 1100×600

new 3-axis vertical machining center, vehicles 850×550

new 3 axis vertical machining center, vehicles 1400×710

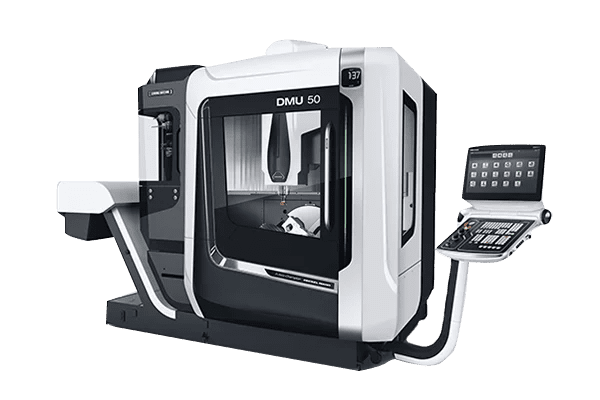

new 5 axis vertical machining center with fully controlled 4 and 5 axis.

new CNC lathe

new 4-axis vertical machining center with fully controlled 4-axis, Travel up to 2000×1000 mm.

new 5 axis vertical machining center DMU 50 with fully controlled 4 and 5 axis.

Portal three-coordinate measuring machine with high accuracy Global Classic 07.10.05.

Microdot for marking parts

Laser marker 50W, 300×300

new ACCUTEX AL 500 wire cutter

new Pinnacle VMC 1000 CNC milling machine

new CNC Universal turning-milling center DMG Mori CLX 450 TC

addition of a new warehouse of 356 m2

Installation of a 70kW solar power plant

Offer of services

Own capacities

- machining of various materials on the basis of supplied documentation according to the customer's request

- processing of electronic documentation in DWG, DXF, STP and IGS formats.

- 3.4 and 5-axis machining on vertical machining centers

- CNC turning

- wire cutter

- material separation

- measuring parts and creating measuring protocols on a 3D measuring device

- marking of parts on a laser marker and micropoint

- mechanical assembly of units according to customer requirements

Cooperation services

- surface finishes: anodized, zinc, chromate, blackening, etc.

- electrochemical polishing and mechanical stainless steel polishing

- wet and powder painting

- Ar and CO2 welding

- black and stainless steel sheet processing, laser cutting

References